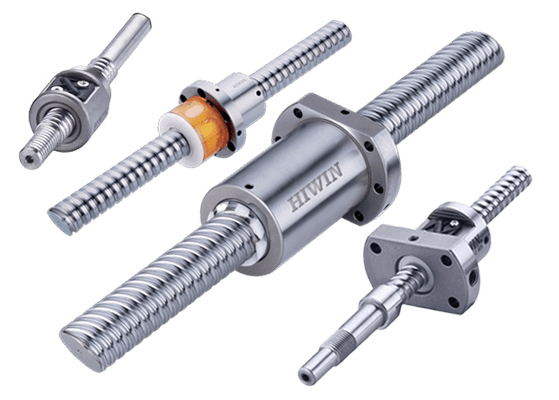

Bearings World offers top-quality Hiwin Ball Screws UAE, designed to meet the highest standards of precision, performance, and durability. Our products are trusted by industries and businesses across Dubai, Abu Dhabi, Sharjah, and other Emirates for their reliability and smooth operation.

Our Hiwin Ball Screws UAE are engineered to provide optimal motion control, reduce wear and tear, and improve the efficiency of machinery across automotive, industrial, and heavy-duty applications. Bearings World ensures that each product is manufactured with high-quality materials and strict quality control for maximum performance.

Why Bearings World Stands Out

Precision & Performance: Each Hiwin Ball Screws UAE is crafted for accuracy and reliable motion.

Extensive Range: Including Hiwin Ball Screws Dubai, Hiwin Ball Screws Abu Dhabi, and Hiwin Ball Screws Sharjah.

Durability: Built to endure heavy loads, continuous operation, and harsh environments.

Expert Assistance: Technical support for installation, maintenance, and selection.

Cost-Effective: High-quality solutions without compromising your budget.

Applications Across Industries

Our Hiwin Ball Screws UAE are perfect for:

Automotive Hiwin Ball Screws UAE – Smooth motion for cars and trucks

Truck Hiwin Ball Screws UAE – Heavy-duty performance for commercial vehicles

Heavy Duty Hiwin Ball Screws UAE – Industrial machinery and factory automation

Precision Hiwin Ball Screws UAE – Robotics, CNC machines, and high-accuracy systems

With Hiwin Ball Screws Ajman, Hiwin Ball Screws Fujairah, and Hiwin Ball Screws Ras Al Khaimah, Bearings World ensures operational efficiency in all environments.

Key Advantages

Minimized friction for smoother motion

Reduced vibration and noise

Extended operational life of equipment

Lower maintenance costs

Environment-resistant components

From Front Hiwin Ball Screws UAE to Rear Hiwin Ball Screws UAE, Bearings World delivers versatile solutions for all applications.

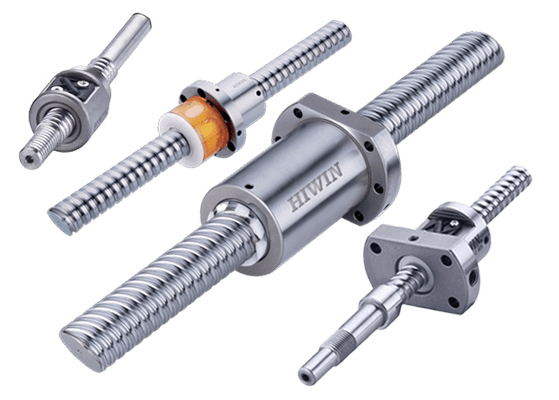

Our Product Portfolio

High Performance Hiwin Ball Screws UAE – For high-speed operations

Durable Hiwin Ball Screws UAE – Long-lasting reliability

Affordable Hiwin Ball Screws UAE – Cost-effective solutions

Precision Hiwin Ball Screws UAE – Perfect for high-accuracy tasks

Car Hiwin Ball Screws UAE – Automotive-focused designs

Commercial Vehicle Hiwin Ball Screws UAE – Optimized for heavy-duty use

Every product undergoes strict quality checks to ensure durability and peak performance under demanding conditions.

Why Industries Choose Us

Industries across the UAE rely on Hiwin Ball Screws UAE from Bearings World because our products:

Enhance operational efficiency

Reduce energy loss and wear

Deliver smooth, consistent motion

Extend machinery and equipment lifespan

Emirates-Wide Availability

We provide support and delivery in:

Hiwin Ball Screws Dubai

Hiwin Ball Screws Abu Dhabi

Hiwin Ball Screws Sharjah

Hiwin Ball Screws Ajman

Hiwin Ball Screws Fujairah

Hiwin Ball Screws Ras Al Khaimah

Our network ensures you can access Hiwin Ball Screws UAE wherever your operations are based.

Customer-Focused Solutions

Bearings World offers tailored guidance for:

Selecting the ideal product for your system

Installation and maintenance tips

On-site technical support

We ensure that every Hiwin Ball Screws UAE product integrates seamlessly into client operations, maximizing efficiency and reducing downtime.

Technical Excellence

Our components are engineered for precision, durability, and performance. Bearings World uses high-grade materials and rigorous testing to ensure smooth motion, minimal maintenance, and extended lifespan.

Trusted & Reliable

Bearings World is committed to providing authentic, high-quality Hiwin Ball Screws UAE from trusted manufacturers. Clients benefit from reliable performance, compliance with international standards, and solutions designed for long-term success.

Bearings World Auto spare parts Trading LLC, Sharjah br. hold pride in introducing ourselves as the part of Bearings world group which is one of the leading source for all types of bearings in U.A.E market.

Copyright © 2025 Bearings World. All Rights Reserved. Powered by Adsonz