Bearings World is a trusted name when it comes to Deep Groove Ball Bearings UAE, supplying industries, automotive applications, and engineering companies across Dubai, Abu Dhabi, Sharjah, Ajman, Ras Al Khaimah, Fujairah, and Umm Al Quwain. Known for durability, precision, and high performance, our range of Deep Groove Ball Bearings UAE is designed to handle radial and axial loads with efficiency.

Whether you need Deep Groove Ball Bearings Dubai, Deep Groove Ball Bearings Abu Dhabi, or Deep Groove Ball Bearings Sharjah, Bearings World ensures reliable supply, competitive pricing, and premium quality.

What Are Deep Groove Ball Bearings?

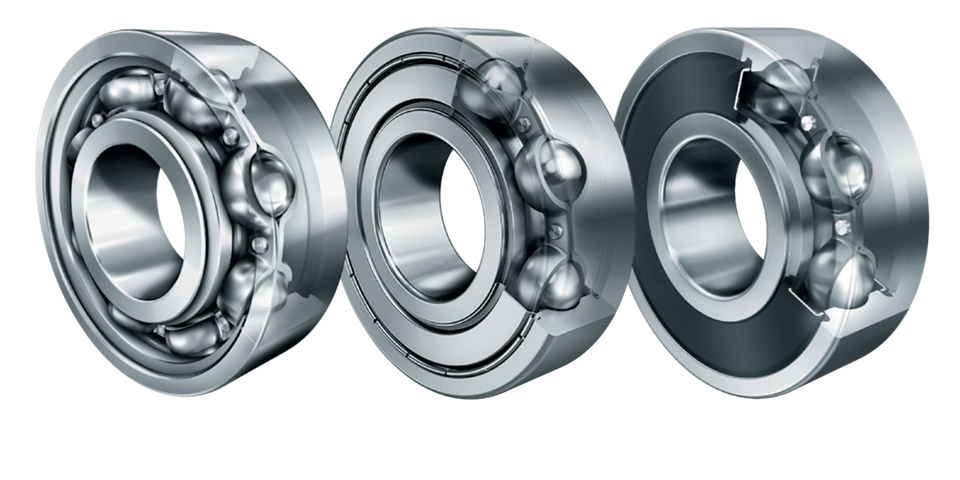

Deep groove ball bearings are the most widely used type of rolling bearings in the world. They are versatile, reliable, and capable of handling both radial and axial loads. Bearings World supplies Single Row Deep Groove Ball Bearings UAE, Double Row Deep Groove Ball Bearings UAE, and advanced types like High Precision Deep Groove Ball Bearings UAE for industries that demand accuracy and long service life.

Types of Deep Groove Ball Bearings

As a premium Deep Groove Ball Bearings Supplier UAE, Bearings World offers:

Single Row Deep Groove Ball Bearings UAE – Compact design for high-speed applications.

Double Row Deep Groove Ball Bearings UAE – Greater load-carrying capacity.

Stainless Steel Deep Groove Ball Bearings UAE – Excellent resistance to corrosion.

Sealed Deep Groove Ball Bearings UAE – Maintenance-free, ideal for dusty or wet conditions.

Open Type Deep Groove Ball Bearings UAE – For applications where sealing is not required.

Miniature Deep Groove Ball Bearings UAE – Perfect for small devices and precision instruments.

Large Deep Groove Ball Bearings UAE – Heavy-duty applications in industries and power plants.

Design Variations, Materials, and Manufacturing Process

The versatility of rolling element bearings arises not only from their performance but also from the diversity of designs available. Engineers can select from a wide range of configurations, each offering unique strengths tailored to specific applications.

Common Design Variations

Single-Row Design

This is the most widely used type, featuring a single row of rolling elements. It is compact, cost-effective, and capable of handling moderate radial and axial loads.Double-Row Design

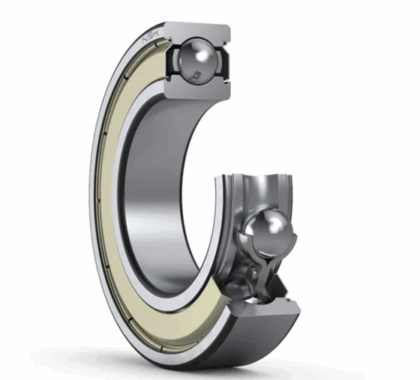

Incorporating two rows of rolling elements, this design offers higher load capacity and greater rigidity. It is particularly useful in applications where alignment is critical or when loads are heavier.Sealed Units

These designs come with integrated seals that protect the internal components from dust, moisture, and other contaminants. They are often pre-lubricated, reducing maintenance needs.Shielded Variants

Unlike sealed units, shielded types use metal covers to protect against larger debris while still allowing limited relubrication if needed.Angular Contact Versions

These are optimized for applications requiring high precision and the ability to carry combined loads, especially axial loads in one direction.Thin Section Models

Designed for environments where space and weight are critical, such as robotics or aerospace, thin-section variants offer compactness without sacrificing performance.High-Speed Configurations

Specially engineered for applications with extremely high rotational speeds, these models minimize friction and heat buildup, ensuring reliable operation.

Materials Used

The choice of materials plays a significant role in determining durability, resistance, and performance.

High-Carbon Chrome Steel: The most common material, offering a balance of strength, wear resistance, and affordability.

Stainless Steel: Provides resistance to corrosion and is widely used in food processing, medical equipment, and environments exposed to moisture.

Ceramic Hybrids: Combining steel rings with ceramic rolling elements, these are ideal for high-speed and high-temperature applications due to reduced friction and greater heat resistance.

Polymers and Composites: Used in specific industries where lightweight, noise reduction, or chemical resistance is more critical than heavy load capacity.

Heat Treatments

To enhance durability, steel components often undergo heat treatments such as carburizing, quenching, and tempering. These processes improve hardness, fatigue resistance, and overall longevity.

Manufacturing Process

Raw Material Selection

High-quality steel bars or tubes are selected and tested to ensure consistency.Forming the Rings

The steel is cut, forged, and machined into inner and outer rings. Precision machining is crucial to ensure tight tolerances.Rolling Element Production

Balls or rollers are manufactured through forging and grinding processes, ensuring perfect roundness and uniform size.Heat Treatment

Both rings and rolling elements are heat-treated to enhance strength and wear resistance.Grinding and Superfinishing

The raceways and rolling elements undergo multiple grinding operations followed by polishing for smooth surfaces. This minimizes friction and noise.Assembly

Rolling elements, cages, and rings are carefully assembled under controlled conditions to prevent contamination.Lubrication and Sealing

Depending on design, grease or oil is added, and seals or shields are installed.Inspection and Quality Control

Each unit undergoes rigorous inspection using advanced measurement tools to verify dimensions, surface finish, and performance.

Advances in Manufacturing

Modern technology has significantly improved efficiency and performance in production. Automation, robotics, and computer-controlled grinding machines ensure accuracy, while non-destructive testing methods detect hidden flaws. 3D modeling and simulation tools also help engineers predict performance under different conditions, leading to better customization.

Coatings and Treatments

To further enhance performance, manufacturers apply specialized coatings:

Phosphate Coating: Adds corrosion resistance.

Teflon Coating: Reduces friction and improves sliding performance.

Black Oxide Treatment: Increases resistance to wear and moisture.

Advanced Ceramic Coatings: Provide extra protection in extreme environments.

Applications Across the UAE

Bearings World provides Automotive Deep Groove Ball Bearings UAE, Industrial Deep Groove Ball Bearings UAE, and Custom Deep Groove Ball Bearings UAE to meet diverse needs. These bearings are widely used in:

Automobiles and motorcycles

Conveyor systems

Electrical motors and pumps

Industrial machinery

Household appliances

Heavy equipment in construction and oilfields

Whether it’s Deep Groove Ball Bearings Fujairah, Deep Groove Ball Bearings Ras Al Khaimah, or Deep Groove Ball Bearings Umm Al Quwain, we ensure coverage across all Emirates.

Why Choose Bearings World?

As a specialized Deep Groove Ball Bearings Supplier UAE, we guarantee:

✅ High-quality OEM and aftermarket products

✅ Wide stock availability for immediate supply

✅ Wholesale and retail options

✅ Precision engineering for long-lasting durability

✅ Distribution across all UAE Emirates

With Bearings World, customers get reliable Deep Groove Ball Bearings UAE solutions tailored to their specific requirements.

Distribution Network

Deep Groove Ball Bearings Dubai

Deep Groove Ball Bearings Abu Dhabi

Deep Groove Ball Bearings Sharjah

Deep Groove Ball Bearings Ajman

Deep Groove Ball Bearings Ras Al Khaimah

Deep Groove Ball Bearings Fujairah

Deep Groove Ball Bearings Umm Al Quwain

No matter your location, Bearings World ensures fast delivery of Deep Groove Ball Bearings UAE for all industries.

Reliable Performance and Applications

The role of these components in machinery is critical. Their precision and durability help ensure smooth operation across a wide range of mechanical systems. By minimizing friction, they extend the lifespan of equipment and reduce the likelihood of unexpected breakdowns.

Ensures stability in rotating systems

Reduces heat build-up and energy loss

Supports both light-duty and heavy-duty operations

Enhances efficiency in high-speed applications

Material Choices and Benefits

Different materials are selected depending on the operating conditions and specific industry requirements. Choosing the right material improves resistance to wear, corrosion, and extreme temperatures.

Stainless steel: Ideal for corrosion resistance in challenging environments

Alloy steel: Provides strength and durability for demanding use

Specialized polymers: Reduce friction and weight for specific applications

Engineering Design and Variations

The design flexibility allows them to be adapted for countless applications. Options with shields or seals provide additional protection, while open types are well suited for clean and controlled environments.

Sealed designs help block dust, moisture, and contaminants

Shielded types provide long service life with reduced maintenance

Open versions allow easy inspection and lubrication

Industrial and Automotive Uses

These components are widely utilized in sectors ranging from automotive to heavy engineering. Their ability to perform under diverse loads makes them indispensable in many fields.

Automotive systems such as gearboxes, engines, and wheels

Conveyor systems and production machinery

Household appliances requiring quiet and smooth operation

Power tools and compact equipment with high rotational speed

Advantages for End Users

Users benefit from consistent performance, cost savings, and reduced maintenance downtime. By relying on high-quality components, industries achieve better results in both efficiency and safety.

Lower operational costs through reduced wear

Extended service intervals for machinery

Improved reliability across various applications

Where can I buy reliable Deep Groove Ball Bearings UAE for industrial and automotive applications?

You can source high-quality Deep Groove Ball Bearings UAE from Bearings World, a trusted supplier across Dubai, Abu Dhabi, Sharjah, Ajman, Ras Al Khaimah, Fujairah, and Umm Al Quwain. We provide single-row, double-row, stainless steel, sealed, and custom solutions suitable for automotive, industrial, and heavy-duty applications. With wide stock availability and professional support, Bearings World ensures reliable performance and fast delivery across all Emirates.

Bearings World Auto spare parts Trading LLC, Sharjah br. hold pride in introducing ourselves as the part of Bearings world group which is one of the leading source for all types of bearings in U.A.E market.

Copyright © 2025 Bearings World. All Rights Reserved. Powered by Adsonz