At Bearing World, we specialize in providing top-notch Needle Roller Bearing UAE solutions for industrial, automotive, and mechanical applications. Our bearings are designed to deliver maximum performance, durability, and precision. By leveraging our extensive network of suppliers and distributors across the UAE, including Dubai, Sharjah, and Abu Dhabi, we ensure our clients receive reliable products for a wide range of machinery and equipment.

Why Choose Needle Roller Bearings from Bearing World?

- High load capacity in a compact design

- Superior durability and long operational life

- Precision engineering for smooth rotation

- Compatibility with various industrial and automotive machinery

- Availability of custom and standard sizes to meet specific requirements

- Fast delivery across the UAE

Our Product Range

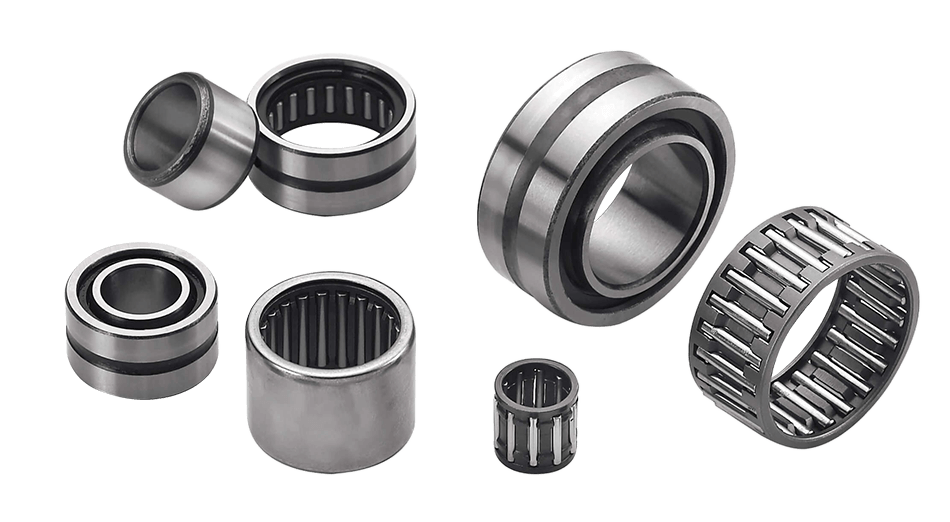

At Bearing World, we offer a comprehensive range of needle roller bearings to meet diverse industrial needs. Some of our key offerings include:

- Needle roller bearing supplier UAE – Reliable supply of standard and custom bearings

- Needle roller bearing distributor UAE – Efficient distribution network for seamless delivery

- Industrial needle roller bearings UAE – Designed for heavy machinery and industrial use

- Precision needle bearings UAE – High-accuracy bearings for sensitive mechanical applications

- Heavy duty needle roller bearings UAE – Built for extreme load handling and reliability

- Automotive needle bearings UAE – Designed for cars, trucks, and other vehicles

- Sealed needle roller bearings UAE – Maintenance-free and protected from contaminants

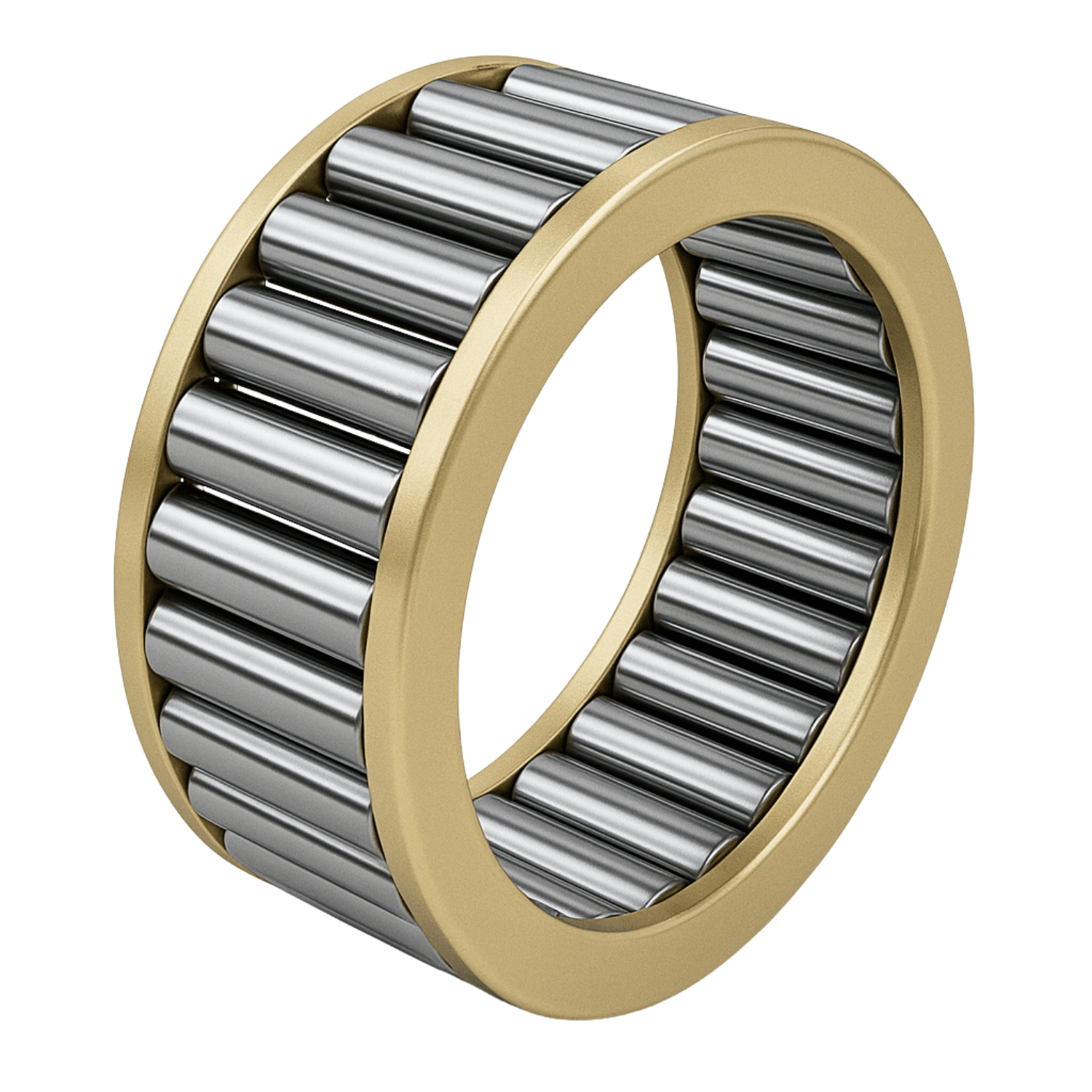

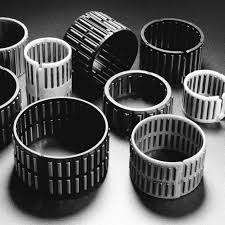

- Caged needle roller bearings UAE – Engineered for optimal load distribution

- Miniature needle roller bearings UAE – Compact bearings for small machinery and equipment

- High load needle bearings UAE – Handles significant radial loads efficiently

- Stainless steel needle roller bearings UAE – Corrosion-resistant bearings for harsh environments

- Drawn cup needle roller bearings UAE – Lightweight and precise for assembly applications

- Thrust needle roller bearings UAE – Designed for axial load management

- Radial needle roller bearings UAE – Ensures smooth radial motion

- Axial needle roller bearings UAE – Specialized for axial load applications

- Needle roller bearing manufacturers UAE – High-quality products directly from trusted manufacturers

- Custom needle roller bearings UAE – Tailored bearings to meet specific industrial needs

- Needle roller bearing price UAE – Competitive pricing for bulk and single orders

- Needle roller bearing catalog UAE – Comprehensive catalog featuring all types and sizes

- Top needle roller bearing brands UAE – Only the best brands for reliability and performance

- Needle Roller Bearing Supplier Dubai – Convenient access to bearings in Dubai

- Needle Roller Bearing Supplier Sharjah – Fast delivery and support in Sharjah

- Needle Roller Bearing Supplier Abu Dhabi – Extensive stock for Abu Dhabi industries

Applications of Needle Roller Bearings

Needle roller bearings are widely used in several industries due to their compact size and high load-bearing capability:

- Automotive manufacturing: transmissions, engines, and drive systems

- Industrial machinery: presses, pumps, and motors

- Aerospace and aviation: precision machinery and rotor assemblies

- Robotics: high-speed motion applications

- Heavy equipment: construction, mining, and agricultural machines

- Electrical appliances: motors and mechanical assemblies

Benefits of Using Needle Roller Bearings

- Reduced friction for higher efficiency

- Compact size saves space in machinery

- High load-bearing capacity

- Long operational life reduces maintenance costs

- Precision engineering enhances machine performance

- Easy installation and replacement

Why Choose Bearing World in UAE?

- Trusted Needle Roller Bearing UAE supplier with years of experience

- Wide range of products catering to industrial, automotive, and mechanical applications

- Strong distribution network across Dubai, Sharjah, and Abu Dhabi

- Competitive pricing and bulk order support

- Access to genuine brands and custom solutions

- Dedicated customer support and technical guidance

How to Select the Right Needle Roller Bearing

Selecting the right bearing depends on:

- Load capacity and type (radial or axial)

- Operating speed and temperature

- Environmental conditions (humidity, dust, corrosion)

- Size and dimensional constraints

- Specific machinery requirements

Tips:

- Always check the manufacturer specifications

- Consult with a trusted supplier like Bearing World for expert advice

- Opt for sealed or stainless steel bearings for harsh conditions

- Ensure proper lubrication for optimal performance

Maintenance and Care Tips

- Regularly inspect for wear and tear

- Use proper lubrication to reduce friction

- Avoid contamination with dust or debris

- Replace damaged or worn-out bearings promptly

- Store bearings in dry and clean conditions

What factors should I consider when choosing a needle roller bearing in the UAE?

When selecting a needle roller bearing, consider load capacity, operating speed, environment conditions, material quality, and precision requirements. Partnering with a trusted supplier ensures you get high-performance bearings suited for industrial, automotive, and specialized applications, backed by warranty and technical support.

Bearings World Auto spare parts Trading LLC, Sharjah br. hold pride in introducing ourselves as the part of Bearings world group which is one of the leading source for all types of bearings in U.A.E market.

Copyright © 2025 Bearings World. All Rights Reserved. Powered by Adsonz