Spherical roller bearings are one of the most advanced types of rolling element bearings, specifically designed to handle heavy loads, reduce friction, and provide smooth rotation in demanding industrial environments. Their unique design makes them highly versatile, enabling them to withstand misalignment, radial loads, axial loads, and challenging operating conditions. This makes them a preferred choice across industries such as construction, mining, steel, cement, power generation, oil and gas, and various heavy machinery applications.

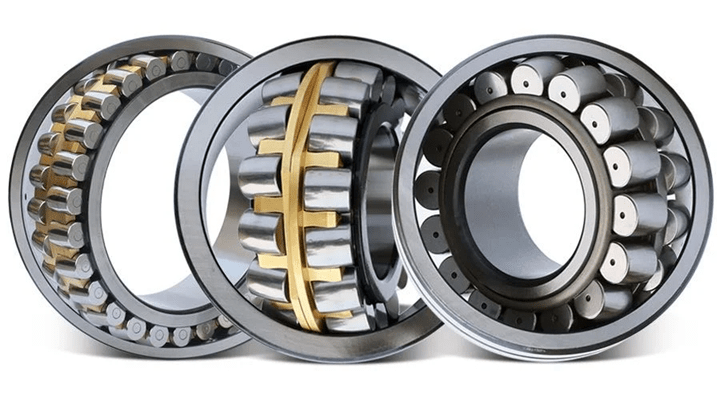

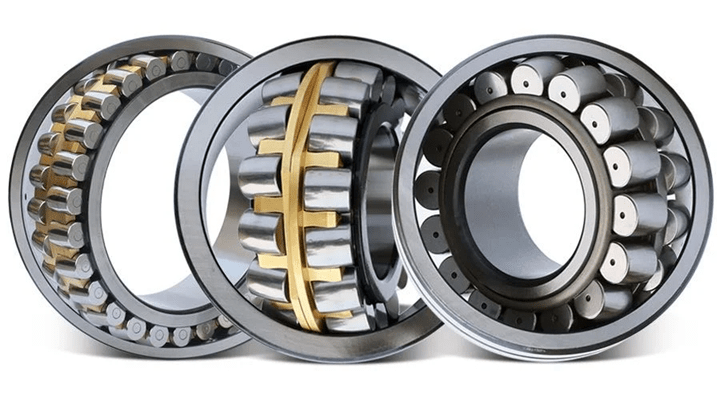

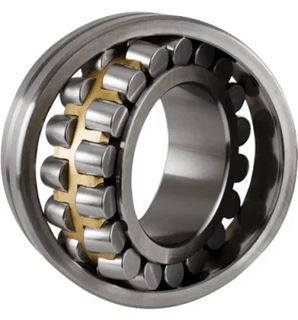

At the heart of a spherical roller bearing lies its distinctive construction. It consists of an inner ring, an outer ring with a spherical raceway, two rows of rollers, and a cage that holds the rollers in position. Unlike other bearing types, the spherical raceway of the outer ring allows the rollers to self-align, meaning they can adjust to shaft deflections or misalignments between the shaft and the housing. This self-aligning feature greatly reduces stress and wear, ensuring a longer service life even in harsh working conditions.

Design and Construction

The rollers inside this bearing are barrel-shaped, which is the origin of the term “spherical.” Each roller is precisely engineered to distribute load evenly across the contact surfaces. This minimizes friction and reduces heat generation, allowing the bearing to operate at higher speeds without compromising efficiency. The cages, typically made of steel or brass, are designed to maintain proper spacing between rollers, ensuring smooth rotation and preventing contact between rolling elements.

Another crucial aspect of their design is the capacity to accommodate both radial and axial loads simultaneously. Radial loads act perpendicular to the shaft, while axial loads act parallel to the shaft. Many bearings can handle only one of these load types efficiently, but spherical roller bearings are engineered to manage both, making them suitable for applications with combined stresses.

Performance and Durability

One of the most important performance characteristics is their ability to operate under severe misalignment. Shafts in heavy-duty machinery often bend or shift slightly during operation. In standard bearings, this would cause uneven stress distribution and premature failure. However, spherical roller bearings compensate for such misalignments, protecting both the bearing and the associated machinery.

They are also known for their exceptional load-carrying capacity. Because of their two rows of rollers and large contact area, they can support significantly higher loads compared to other bearing types of similar size. This makes them ideal for heavy industrial use where equipment is exposed to constant vibration, shock loads, and continuous operation.

Heat resistance and lubrication efficiency are equally important for extending bearing life. High-quality spherical roller bearings are manufactured with advanced heat treatment processes, enhancing hardness and dimensional stability. They are also designed to optimize lubrication flow, ensuring that grease or oil reaches all critical surfaces. Some variants are even produced with specialized seals to prevent contamination by dust, dirt, or moisture, which can otherwise shorten service life.

Industrial Applications

The versatility of spherical roller bearings allows them to be used in a wide range of industries:

Mining and Quarrying: Equipment like crushers, conveyors, and vibrating screens rely heavily on bearings that can handle extreme loads and vibrations. Spherical roller bearings are perfect for these conditions, ensuring continuous operation with minimal downtime.

Steel and Metal Processing: Rolling mills, continuous casting machines, and furnaces operate under extreme temperatures and pressures. Bearings used here must withstand heavy stress, and spherical roller bearings deliver the required durability.

Cement Plants: Crushers, kilns, and grinding mills place heavy demands on bearings. The self-aligning ability of spherical roller bearings helps maintain performance despite misalignments caused by thermal expansion.

Construction Equipment: Excavators, loaders, and cranes require robust components that can tolerate both high loads and environmental challenges. Spherical roller bearings are widely used in these machines.

Power Generation: Turbines, gearboxes, and generators operate continuously and require bearings that provide reliability. The efficiency and endurance of spherical roller bearings make them an excellent choice in this sector.

Oil and Gas Industry: Offshore and onshore drilling rigs, pumps, and compressors often work in corrosive and harsh environments. Specially coated spherical roller bearings provide resistance against rust and moisture.

Types and Variations

Several variations of spherical roller bearings are available to suit different applications. For example:

Sealed bearings: Equipped with integral seals to protect against contamination and reduce maintenance requirements.

Split bearings: Designed for easy installation and removal in applications where access is limited.

High-temperature bearings: Manufactured with materials and lubricants that withstand extreme heat.

Special coatings: Bearings with coatings such as black oxide or nickel plating offer enhanced corrosion resistance.

Each variation is tailored to improve performance in specific conditions, whether it be protection against dust, resistance to water, or the ability to operate at high speeds.

Maintenance and Care

Although spherical roller bearings are engineered for durability, regular maintenance is essential to maximize service life. Proper lubrication is critical; insufficient lubrication can cause overheating, while excessive lubrication can lead to churning and energy loss. Condition monitoring through vibration analysis, temperature checks, and regular inspections helps in identifying early signs of wear or damage.

In addition, ensuring that bearings are installed correctly is crucial. Misalignment during installation, improper handling, or the use of incorrect tools can reduce the efficiency of even the highest-quality bearings. Many manufacturers provide detailed installation guides and recommend specific lubricants to ensure optimal performance.

Advantages Over Other Bearings

Compared to cylindrical or tapered roller bearings, spherical roller bearings offer several unique advantages:

Self-aligning capability to compensate for shaft deflections.

High load capacity in both radial and axial directions.

Durability in harsh environments with shocks and vibrations.

Longer service life due to even load distribution.

Versatility across various industries and machinery.

These characteristics make them one of the most reliable and cost-effective bearing solutions for heavy-duty applications.

Conclusion

Spherical roller bearings are essential components in modern industry, combining strength, adaptability, and durability in one design. Their ability to handle misalignment, support heavy loads, and resist challenging conditions sets them apart from many other bearing types. With proper installation, maintenance, and selection based on application needs, these bearings can deliver long-lasting performance and reduce operational downtime.

By incorporating advanced materials, innovative engineering, and specialized variations, manufacturers continue to improve the efficiency and reliability of spherical roller bearings. Whether used in mining, steel production, cement plants, construction machinery, or power generation, they remain an indispensable solution for industries that demand strength and consistency.

Spherical Roller Bearing

Spherical Roller Bearing is one of the most trusted and in-demand industrial components for heavy-duty applications. Known for their strength, durability, and ability to handle both radial and axial loads, these bearings are widely used across industries like mining, steel, cement, oil and gas, power generation, and construction. Bearings World is a reliable destination for anyone looking for high-quality Spherical Roller Bearing supplier UAE, providing a wide range of options to meet the requirements of different sectors.

Why Choose Spherical Roller Bearing ?

A Spherical Roller Bearing distributor UAE plays an important role in delivering products that offer long service life and high load-carrying capacity. Unlike conventional bearings, a spherical roller bearing can automatically adjust to misalignments, shaft deflections, and heavy vibrations. This makes them the ideal choice for industries where machinery runs under extreme pressure.

In places like Dubai and Sharjah, the demand for Spherical Roller Bearing dealer Dubai and Spherical Roller Bearing Sharjah has been increasing due to rapid industrial growth. Companies prefer working with a trusted Spherical Roller Bearing stockist UAE because it ensures genuine products, competitive prices, and reliable performance.

Features of Spherical Roller Bearing

The construction of a Spherical Roller Bearing company UAE product includes an inner ring, outer ring, two rows of rollers, and a cage that holds them in place. This unique design allows the bearing to withstand harsh operating conditions. Customers looking for High quality Spherical Roller Bearing often consider specifications like heat treatment, cage material, lubrication, and sealing system.

Some of the top features include:

Ability to handle both radial and axial loads.

Self-aligning design to reduce stress from shaft misalignment.

Long service life with proper lubrication.

Versatility in multiple industries.

Applications of Spherical Roller Bearing

Industries across the UAE rely on Industrial Spherical Roller Bearing UAE to keep machinery operating efficiently. For example:

In mining, they are used in crushers, conveyors, and vibrating screens.

In cement plants, they are essential for kilns, crushers, and grinding mills.

In steel industries, Heavy duty Spherical Roller Bearing UAE supports rolling mills and furnaces.

In construction, cranes, excavators, and loaders depend on bearings that resist shock loads.

In oil and gas, sealed and coated bearings prevent corrosion from harsh conditions.

Because of their wide range of uses, the search for the Best Spherical Roller Bearing UAE continues to grow among companies that want durable and cost-effective solutions.

Types and Variants

Customers can find several variations from a Spherical Roller Bearing wholesaler UAE:

Sealed Bearings – Protect against dust and dirt.

Split Bearings – Simplify installation and replacement.

High-Temperature Bearings – Designed for industries like steel and cement.

Special Coated Bearings – Provide corrosion resistance.

Each type ensures that the customer receives the right solution based on the application. With the support of a Spherical Roller Bearing trader UAE, businesses can access the correct product specification and application guidance.

Purchasing from a Reliable Supplier

When buying a Spherical Roller Bearing online UAE, it is important to choose an experienced company like Bearings World that ensures authentic and durable bearings. As a trusted Spherical Roller Bearing shop Dubai, the company provides a complete catalog, competitive prices, and fast delivery.

From Spherical Roller Bearing parts UAE to complete bearing assemblies, customers can rely on professional support. Businesses looking for Spherical Roller Bearing manufacturers UAE often prefer dealers and distributors in UAE because they offer both international brands and locally available options.

Price and Availability

Finding the right Spherical Roller Bearing price UAE depends on factors such as size, type, brand, and sealing options. A professional Spherical Roller Bearing catalog UAE helps customers understand available models and technical details. By working with a Spherical Roller Bearing stockist UAE, businesses can ensure continuous supply and minimize downtime.

Why Bearings World?

Bearings World stands out as a reliable Spherical Roller Bearing company UAE, providing superior quality, wide product range, and expert technical support. Customers prefer sourcing from a dedicated Spherical Roller Bearing distributor UAE who understands the challenges of local industries and offers timely solutions.

Whether you are searching for Spherical Roller Bearing supplier UAE or want to connect with a Spherical Roller Bearing dealer Dubai, this platform ensures that you receive genuine products at competitive rates.

Conclusion

A Spherical Roller Bearing UAE is more than just a component; it is the backbone of heavy industrial operations. With features like self-aligning design, high load capacity, and ability to withstand harsh conditions, it remains the preferred choice for industries across the UAE.

Bearings World, as a reliable Spherical Roller Bearing wholesaler UAE and Spherical Roller Bearing shop Dubai, ensures that customers receive long-lasting solutions for mining, steel, cement, construction, oil, and gas industries. With easy access to Spherical Roller Bearing online UAE, clients can order directly, explore the Spherical Roller Bearing catalog UAE, and benefit from expert advice.

By choosing a trusted Spherical Roller Bearing company UAE, businesses can reduce maintenance costs, extend machinery life, and achieve smooth operations. Whether it’s Heavy duty Spherical Roller Bearing , Industrial Spherical Roller Bearing , or High quality Spherical Roller Bearing , customers in Dubai, Sharjah, and across the UAE can always count on Bearings World for the best solutions.

Bearings World Auto spare parts Trading LLC, Sharjah br. hold pride in introducing ourselves as the part of Bearings world group which is one of the leading source for all types of bearings in U.A.E market.

Copyright © 2025 Bearings World. All Rights Reserved. Powered by Adsonz