About Tapered Roller Bearings

A Tapered Roller Bearing UAE is designed to handle both radial and axial loads effectively. Unlike other bearing types, its unique geometry allows it to manage combined loads with superior efficiency. These bearings are widely used in heavy-duty applications, including automotive, industrial, and construction sectors.

Key Features of Tapered Roller Bearing UAE:

High load-carrying capacity

Designed for radial and axial loads

Long service life with proper lubrication

Precision design for consistent performance

Suitable for high-speed and heavy-duty machinery

Why Choose Tapered Roller Bearing UAE?

The demand for Tapered Roller Bearing UAE is growing rapidly across industries. From automobiles to industrial gearboxes, these bearings ensure smooth operation and reliability. Businesses prefer them due to:

Durability – Designed for long operational life.

Versatility – Suitable for multiple industries.

Performance – Can withstand extreme working conditions.

Availability – Easily sourced from trusted distributors and suppliers across the UAE.

Industrial Applications

Tapered Roller Bearing UAE plays an essential role in:

Automotive Industry

Used in wheel hubs, gearboxes, and transmissions.

Provides stable support under heavy loads.

Heavy Machinery

Excavators, loaders, and cranes depend on them.

Handles shock loads and rugged working environments.

Industrial Equipment

Gearboxes, pumps, and conveyor systems.

Ensures precision and smooth functioning.

Aerospace and Railways

High-speed and heavy-load handling capabilities.

Reliability in critical applications.

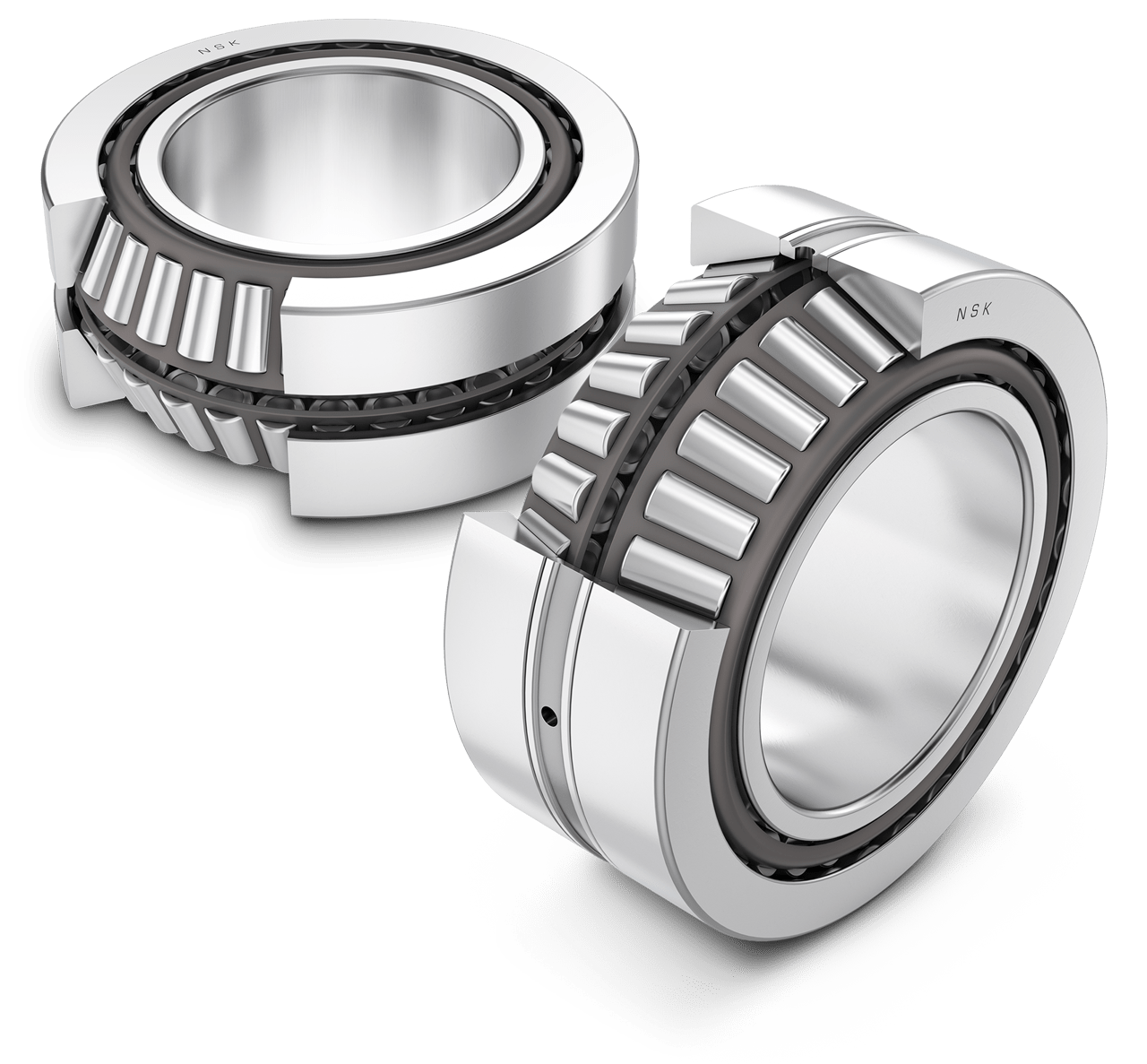

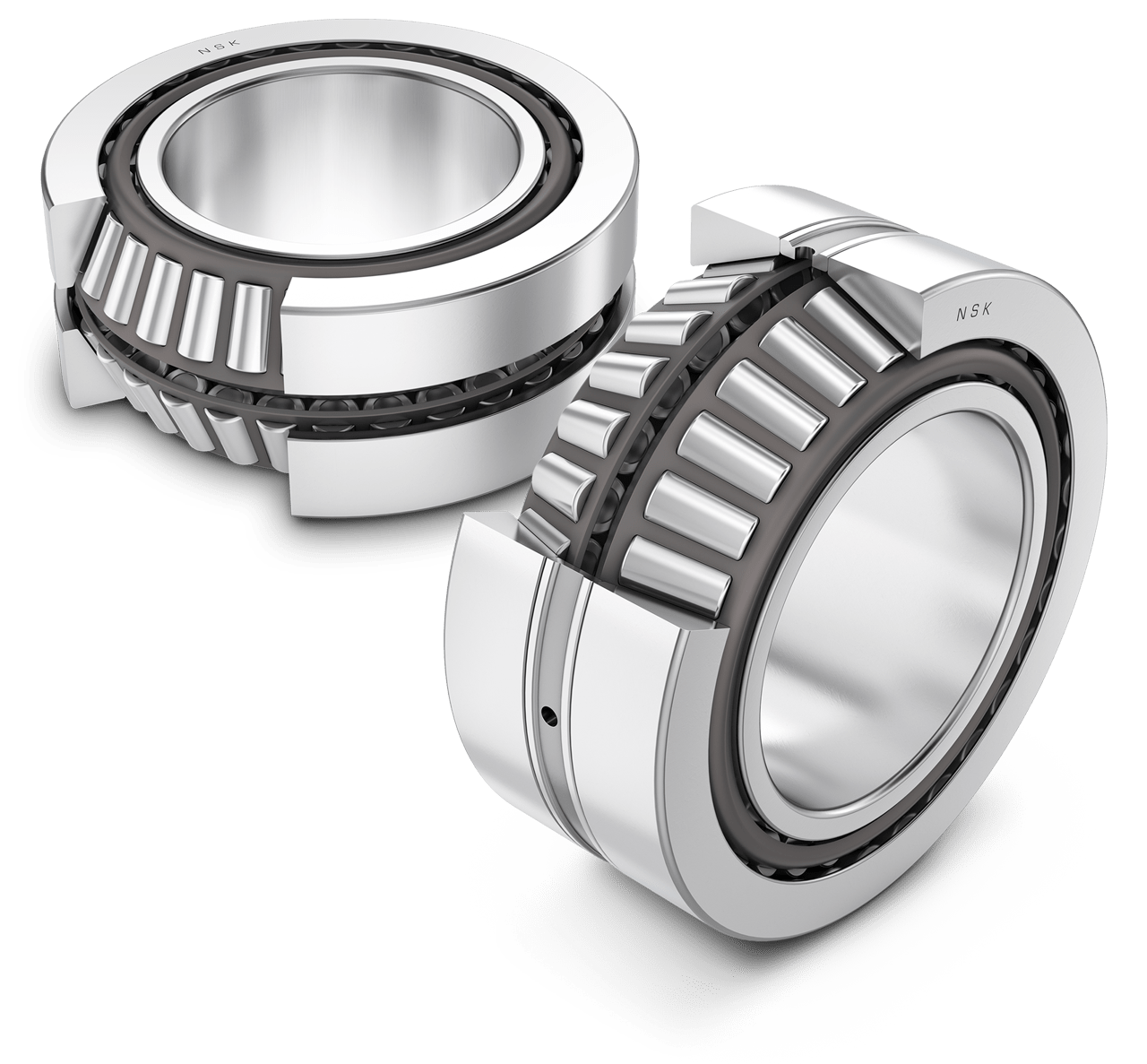

Types of Tapered Roller Bearings

Single Row Tapered Roller Bearings

Handles combined loads efficiently.

Commonly used in automotive and gearboxes.

Double Row Tapered Roller Bearings

Offers higher load capacity.

Suitable for heavy machinery and construction equipment.

Sealed Tapered Roller Bearings

Protects against dust, dirt, and water.

Reduces maintenance requirements.

Stainless Steel Tapered Roller Bearings

Ideal for marine and food-grade applications.

Resistant to corrosion and extreme conditions.

Custom Tapered Roller Bearings

Designed for unique industrial needs.

Available with OEM solutions.

Benefits of Using Tapered Roller Bearing UAE

Extended machinery life

Reduced friction and heat

Lower maintenance costs

Improved efficiency

Reliability in critical applications

Why UAE is a Hub for Bearings

The UAE has become a global hub for sourcing high-quality bearings, including Tapered Roller Bearing UAE. With world-class infrastructure, global trade links, and a strong network of authorized distributors, businesses can easily procure SKF, FAG, NSK, Timken, and other global brands.

Buying Guide for Tapered Roller Bearing UAE

When selecting the right bearing, consider:

Load Requirements – Choose based on radial or axial load.

Speed Rating – Ensure compatibility with machinery speed.

Material Quality – Opt for stainless steel or high-strength alloys.

Sealing Options – Depending on exposure to contaminants.

Supplier Reputation – Always buy from trusted distributors in the UAE.

Tapered Roller Bearing UAE

Overview of Tapered Roller Bearings in UAE

Tapered Roller Bearing UAE is widely used in automotive, industrial, and heavy machinery applications.

Businesses in Dubai, Abu Dhabi, Sharjah, Ajman, Ras Al Khaimah, Fujairah, and Umm Al Quwain rely on Tapered Roller Bearing UAE for durability and performance.

Genuine products from a Tapered Roller Bearing supplier UAE or Tapered Roller Bearing distributor UAE ensure long service life.

Applications in Different Emirates

Tapered Roller Bearing Dubai – essential for vehicles, gearboxes, and machinery.

Tapered Roller Bearing Abu Dhabi – trusted in oilfield equipment and transport industries.

Tapered Roller Bearing Sharjah – reliable for manufacturing and construction sectors.

Tapered Roller Bearing Ajman – used in small and medium-scale industries.

Tapered Roller Bearing Ras Al Khaimah – supplied for marine and port machinery.

Tapered Roller Bearing Fujairah – durable in harsh industrial environments.

Tapered Roller Bearing Umm Al Quwain – dependable for logistics and mechanical systems.

Types of Tapered Roller Bearings

Single row Tapered Roller Bearing UAE – suitable for compact applications.

Double row Tapered Roller Bearing UAE – used in heavy-duty operations.

Heavy-duty Tapered Roller Bearing UAE – preferred for construction and mining machines.

Precision Tapered Roller Bearing UAE – critical in high-accuracy industries.

Automotive Tapered Roller Bearing UAE – ideal for wheel hubs and transmissions.

Industrial Tapered Roller Bearing UAE – supports factories and manufacturing plants.

Sealed Tapered Roller Bearing UAE – protection against dust and contaminants.

Stainless steel Tapered Roller Bearing UAE – used in marine, food, and chemical industries.

Custom Tapered Roller Bearing UAE – tailored for unique applications.

OEM Tapered Roller Bearing UAE – provided for branded machinery.

Bearings World Auto spare parts Trading LLC, Sharjah br. hold pride in introducing ourselves as the part of Bearings world group which is one of the leading source for all types of bearings in U.A.E market.

Copyright © 2025 Bearings World. All Rights Reserved. Powered by Adsonz